DATE: 2016

MODEL: MC 22

Two Comacchio rigs were used for a complex grouting project in Karlsruhe, Germany.

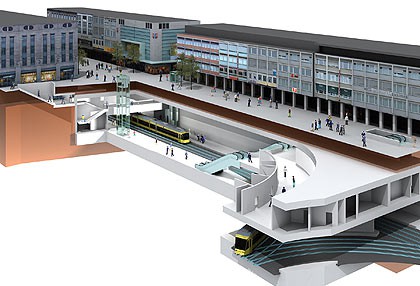

Karlsruhe is the second-largest city in the state of Baden-Württemberg, in southwest Germany. It was one of the first cities to implement an hybrid tram-train system, which consists of tram/light rail trains and commuter/regional rail trains running on the same set of tracks directly into the heart of the city. The increasing passenger numbers required new solutions in order to relieve the surface tram line on the central corridor along Kaiserstraße¸ a bustling shopping boulevard in the city center, and to make the inner city more sustainable, pedestrian-friendly and attractive. At a referendum in 2002, the population of Karlsruhe voted in favor of a combined rail and road tunnel project, known as the “combined solution” (German: “Kombilösung”), aimed to partially transfer underground the currently mostly above-ground tram-train network and to separate tram tracks from car and pedestrian traffic.

The construction works are carried out by a Joint Venture of German Be-Mo Tunneling GmbH and Spanish Fomento de Construcciones y Contratas (FCC). The first phase of the project, comprising the Stadtbahntunnel (a two-track rail tunnel in the east-west direction) and a branch tunnel (so called Südabzweig), started in 2010 and is scheduled to be completed in 2016.

The 250 m long tunnel under Karl-Friedrich-Strasse, going from Marktplatz to Ettlinger Tor, due to the short distance and shallow depth, will be excavated full face according to the conventional NATM method. To counteract the groundwater laying completely above the tunnel and to prevent flooding of the excavation profile, the excavation is carried out using compressed air. Before excavation could start, a complex grouting program was set up to reduce compressed air losses and dangerous blow-outs during NATM excavation. The permeability of the subsoil on a 2 meters thick crown around the excavation area needed to be reduced in order not to exceed the limit of 1•10-7 m/sec. To obtain this, the use of low pressure grouting had been envisaged by the designer. The permeation grouting is carried out starting from autumn 2014 by German based RODIO GmbH Spezialtiefbau, working as a subcontractor of BeMo/FCC.

The project area, located in the high banks of the Rhine river, is formed by an alternation of coarse permeable quaternary gravels and sand layers, with cohesive, 1 to 1.5 m thick silt interlayers located closer to the tunnel elevation.

PVC tube à manchettes (TAMs) are used to provide access for grout injection. The boreholes are drilled vertically and inclined from the Karl-Friedrich-Straße. The project requirements include over 3.000 boreholes, for a total drilling length of nearly 50.000 m. Two Comacchio drill rigs are being used to perform the drillings: one MC22 and one MC1200, both equipped with twin rod rack. Drillings are made by rotary method, using water or cement grout as flushing means. To increase the feed stroke and speed up production, special extensions were mounted on the 12 m long mast of the machines, reaching a drilling depth of 23 m. The R3000 rotary head, designed by Comacchio, providing 2,400 daNm torque, was equipped with an hydraulic chuck and special inserts of 101 mm to handle the drill rods. After drilling, the manchette pipes are installed into the boreholes and secured into place by filling the annulus around them with a weak “sleeve grout” made with a stable cement based suspension.

The allowed borehole deviation was set by the designer to 3% at full length. The deviation of each single drilling is measured using a chain inclinometer. The drilling parameters are registered using a Jean Lutz LT3 system.

Grouting starts when the “sleeve grout” has reached a certain strength, no earlier than 2-3 days after the installation of the TAM pipes. The grouting sequence includes primary and secondary injections. The primary injection is carried out with a stable cement-based suspension on the entire treated area. The secondary grouting is made with a high penetration soft gel only on the outer edge of the section.

The core drillings, carried out to control the quality and homogeneity of the injected soil, showed a fairly good stiffness and homogeneity of the treated soil, thus demonstrating a good penetration of the grouting products.

The excavation work for the tunnel under Karl-Friedrich-Strasse is scheduled to be completed in the summer of 2016.

|

Approximate work quantities |

|

|

Number of grout holes |

3.000 |

|

Total drilled length |

50.000 m |

|

Number of grouting processes |

250.000 |

|

Total injected soil volume |

40.000 m3 |

|

Injected soil volume by gel (collar only) |

21.000 m3 |